News: discover our flexible impeller pumps

Oct 31, 2019

Why use this new type of pumps?

This new type of flexible impeller pumps is particularly suitable for transfers of delicate and fragile fluids such as those used in the sectors of oenology, food processing, chemicals, cosmetics and even pharmaceuticals. These pumps are designed for transferring hydrocarbons as well as for filling, reloading and even drainage!

You can use these pumps in the industry for your systems of filling, transfer or reloading of water softeners. As well as for draining a reservoir, circulating water in cooling towers and even for draining and filling oil sumps.

You may need them for your plumbing to drain the drainage pipes or clogged toilets. Do you work in agriculture? Our pumps can help you fill your water tanks, clean your enclosures and even water your animals! You can also use them to remove condensates or clean your floors.

Operation of our flexible impeller pumps

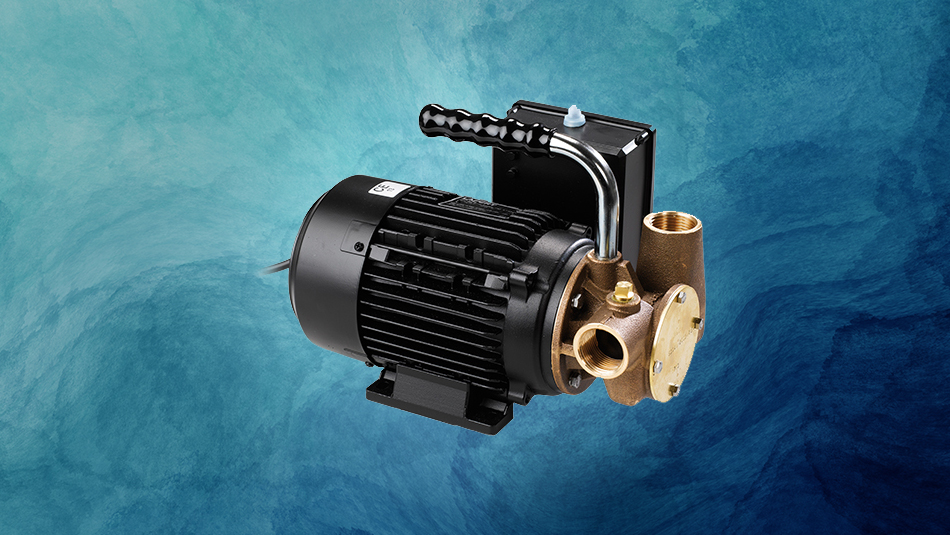

Our pump models can self-prime up to 3 metres! With a bronze body and a stainless steel shaft, these models are resistant and will last for several years, even with regular use. Semi-solid particles as well as abrasive particles can be handled.

Being reversible, they respect the pumped product and cause very little shearing. It is then transferred without pulsing, which again helps to keep the product under optimum conditions of use. The way they work is simple. The turbine deforms the flexible blades, which then suck up the liquid into the pump body, while continuously transferring it to the outlet pipe. It is an effective, yet gentle pumping.

In addition to a self-priming capacity that is able to suck up the product at depths of up to 3 m, these pumps have a reversal system that allows them to change their direction of rotation to send the excess liquid back without any manual intervention. They have a pressure of up to 2.5 bars and a viscosity of up to 500 cP.

There are five pump models available

- The JEP040 pump has a flow rate of 2.1 m3/h and a max. TDH of 15 m. Its weight of 9.5 kilos makes it easily transportable.

- The JEP080 model has a higher flow rate that can reach up to 4.8 m3/h! Heavier at 15.5 kilos, it can however handle larger particles (8 mm as compared to 4 mm for the JEP040 pump).

- JEP34, JEP114 and JEP112 (stainless steel body)